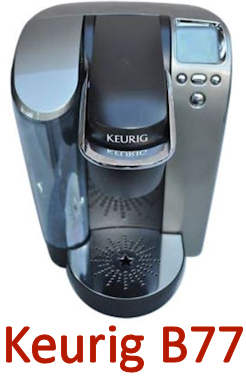

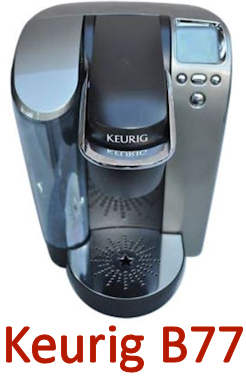

The Single Serve Coffee Machine

Dissecting a Keurig B77

I recently acquired a broken B77 machine. I have the same model purchased in September 2011 and it works fine. From the outside the broken B77 appeared to be in fine shape. Only time and I mean the patient type of time would reveal more.

These, like other models, are ubiquitous in the United States. That is good news as the internet is loaded with many stories, DIY repairs, pitfalls and general information.

I began the disassembly before finding the article linked above. After getting the bottom off I decided I had better take a picture of the screws since there were two different sizes and at least one shorter than the others. To finish removing the bottom you must drill out the pop rivet that attaches the 3 ground wires to the metal bottom. With the bottom off you can remove the plastic spacer that attaches to the case.

Throughout this document I will state some wisdom learned. This first one; these machines were not designed to be repaired. I know this by removing the top. You must pry, very carefully, so as not to break but to expose the plastic latches that hold the top on. Once you can see inside the top by prying the front up somewhat, a long (I used a 9") screwdriver can be used to remove the cover by pressing the latch until it is free to pop open. This is not easy or simple.

With the top removed the outside cover comes off easy after a few screws are removed. The on/off switch must be disconnected so the outside cover can be set aside. This is done by removing the circuit board cover and unplugging the switch. Then, reinstall the switch to make the machine operable without the cover. At this point you can see most of the parts that come into play to make your special cup of coffee. Still hidden are the front buttons and display. At the center of this wonder is an internal tank. It has a stainless steel bottom and a clear plastic top.

I should note here that this machine was stored for some time prior to my acquiring it. I say this because shining a light into the clear tank top reveals floating science like matter in the tank. Time for more wisdom; it is not a good idea to use these occasionally. Since there is no way to purge the contents of the internal tank your science experiment will start the moment you store the machine away. Additionally, these units would not do well in an environment that may freeze because the parts containing water cannot be emptied. The owners manual hints that the unit should be purged (replacing old water with new water) if it has been unused for a long time. The picture shows the material between two pins and the resulting rough surface on the right pin.

I had thought I could clean this matter from the tank by cycling it enough to get vinegar into the tank and letting it sit over a few days. This material was floating and would not dissolve and disappear. Some was also visible on the several stainless steel pins that run through the clear top. Next, I removed a few hoses and that would allow me to empty the tank. I did get some of the material out by doing this but not all of it.

It was at this point I decided even if I could repair this machine I was not going to be consuming anything that had been through it. I switched to diagnose and cannibalize mode.

The information from the internet indicated that one of the two solenoids may be defective. I used a spare 12VDC power supply to operate each solenoid. It turns out the forward solenoid was defective and that condition matches with the observed fault: any cup that is processed is not full and the water reservoir gets increasingly warmer with each cup made as heated water is sent back to the supply reservoir with each cycle.

The internet postings indicated that internal leaks caused most of short life issues with these machines. There was evidence of leaking with this machine indicated by the corroded solenoid and a few screws that had rust deposits. These machines have many moving parts, i.e. solenoids, water pump, air pump, check valves, immersion heater, sensors, etc. These are connected with silicone tubing held tight with cable ties. The machine does have the UL stamp of approval but that is for safety not long life.

The marketing of the single server coffee appliance uses the razor blade model where the machine cost is often discounted to get one hooked on the supply side of the business. You may have heard that Keurig took that a step further by requiring that the K cups be of a blessed type with the version 2.0 machine. They have since been forced to abandon that requirement because of sales tanking and unhappy consumers.

These machines have a place as long as the wisdom above is considered. They are convenient, offer many choices of flavor and save discarding the bottom of the pot each day since they produce a good cup each time. In Connecticut the discarded pods do not go into landfills. These pods are either burned in a trash to energy facility or recycled at a single stream location.

/*